1. Description:

Slurry Pump ZJ series are designed as single-stage, single-suction double-casing centrifugal horizontal slurry pumps. Various of pump speeds make ZJ series pump running under optimum operating conditions. Slurry Pump ZJ series can meet a wide variety of harsh conditions. Slurry pump ZJ series are suitable for handling abrasive and corrosive solids-bearing slurry with maximum density, which are widely used in power, metallurgical, mining, coal and building materials.

Typical Application:

● Concentrate and tailing processing in concentration plant

● Ash and slag removal in power plant

● Coal slurry delivery and heavy media coal preparation

● Transferring slurry in mining operations

● Heavy media coal preparation

● Main auxiliary products in thermal power unit

2. Features:

● High efficiency; energy-saving; light weight; reasonable construction; reliable performance; little vibration; low noise; easy maintenance.

● Various design of the pump speed and versions enable the pump to work even under poor conditions.

● The bearing layer and the wear layer can be separated. And the wet parts are made from strong abrasion resistance high-chrome alloy cast iron.

● Three types of shaft seals, mechanical seal, packing seal and packing combined expeller seal can be adopted.

● The pump discharge can be positioned to 8 directions at intervals of 45 degrees according to need. The inlet is horizontal.

● The medium transferred temperature should not exceed 60ºC. The weight concentration of the mortar should not exceed 45%; mineral slurry, 60%.

● The pumps can be installed in multi-stages for long distance delivery.

● Drive mode: mainly direct connection(DC).

● Lubricating way: 40ZJ-200ZJ adopts grease or oil lubrication according to bearing box structure; 250-500ZJ adopts grease lubrication.

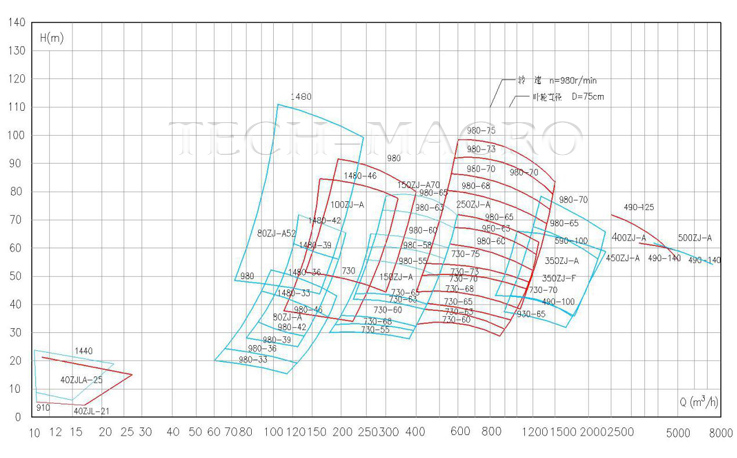

1. Operating Limits

● Discharge Diameter: 40--500 mm

● Flow Capacity:10--8000 m3/h

● Head:2--130 m

2. Materials:

|

Materials Options |

|

Construction |

Standard |

Optional |

|

Wet end parts (Liners,Impellers) |

High chrome alloy (A05, A07, A08, A09, A11, A49, A33, A61……);

Composite ceramics |

The material adopted is usually based on the detailed application, or could be according to the customer’s requirements. |

3. Performance Chart:

Note : Approximate performance of clean water and only for primary model choice.

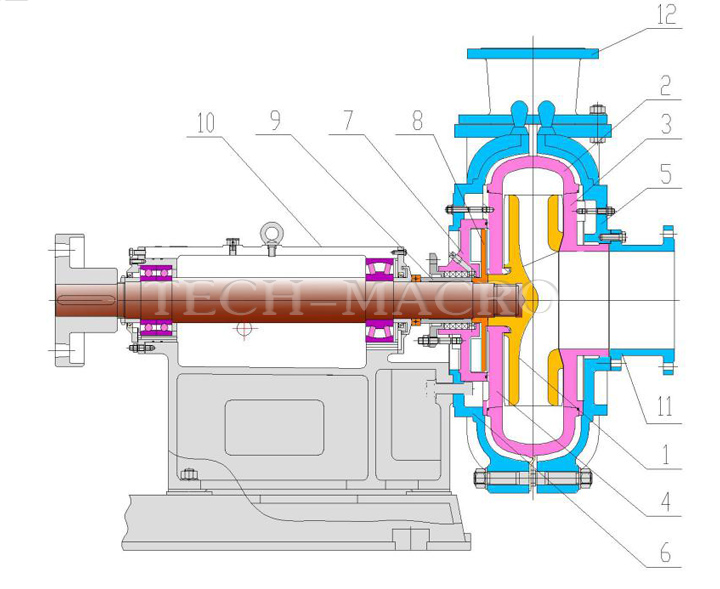

Structure

ZJ series

1 Impeller 2 Volute Casing 3 Throat Bush 4 Back Liner 5 Cover Plate 6 Frame Plate 7 Packing Box 8 Expeller 9 Shaft Sleeve 10 Frame 11 Suction Tube 12 Discharge Tube |